Alexis von Croy stepped up to his second-gen SR22 GTS, top, from a Piper Warrior. He gets it in and out of a 2000-foot turf strip in the Czech Republic.

The Cirrus SR22, with its composite structure, built-in parachute, and comfortable cabin design reminiscent of a sports sedan, stands as one of the most contemporary piston singles in the market. However, flying this aircraft demands rigorous training and diligent maintenance. Additionally, the SR22 has been in production for over 20 years, leading to a diverse selection of used models available for purchase. Despite the variety, it’s important to note that SR22s are currently in high demand.

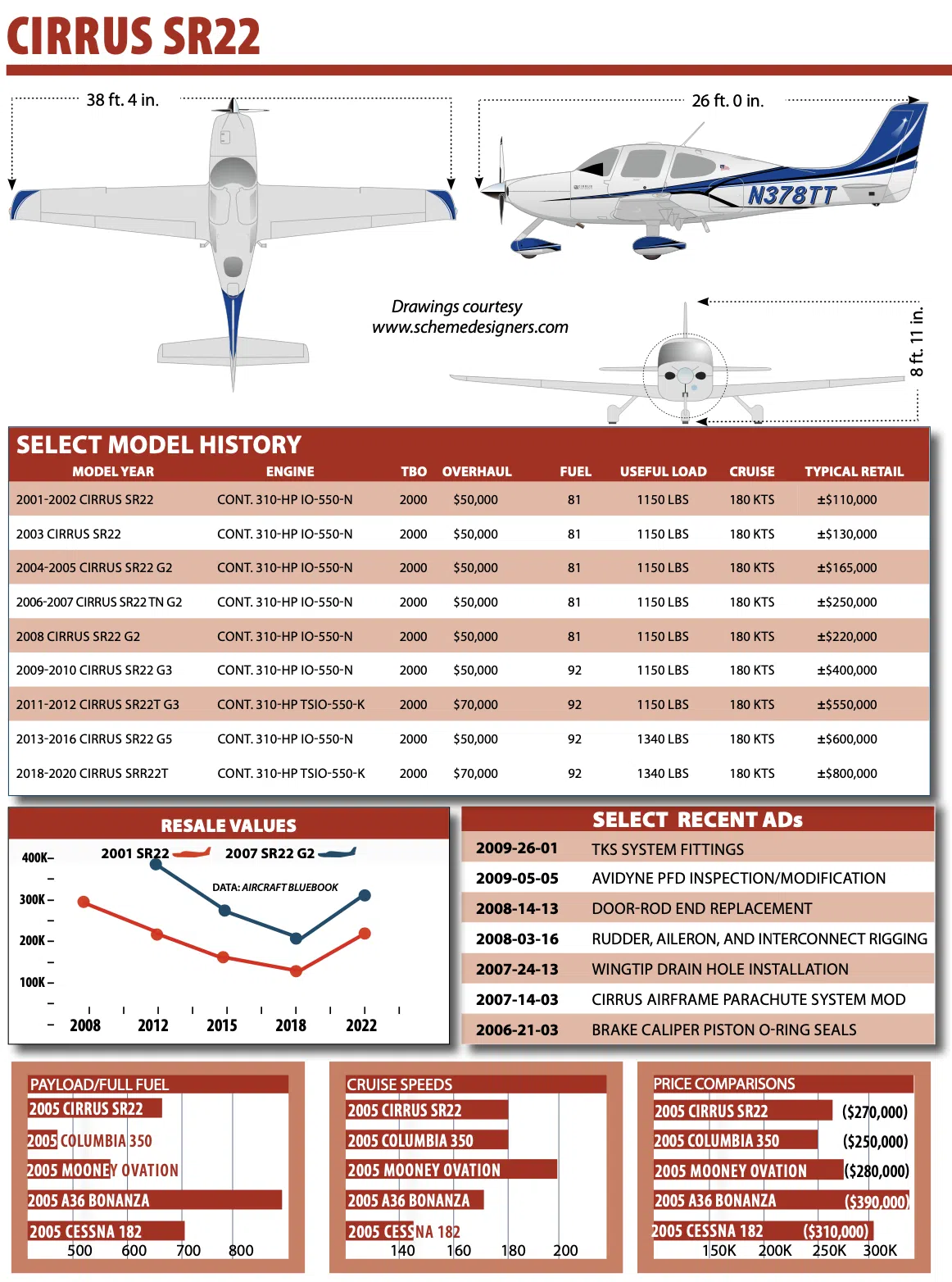

The Fall 2022 Aircraft Bluebook reports the value of a normally aspirated SR22-GS at $410,000, which is nearly on par with its original purchase price back in 2010. Models equipped with new engines, upgraded avionics, and enhancements to the interior and exterior command significantly higher prices.

If you’re considering acquiring a Cirrus SR22, it’s essential to begin with an insurance quote, a well-structured plan for acquiring the necessary training, and a preparedness to act promptly when bidding on newly listed SR22s, as they tend to sell swiftly.

You’ve probably heard the remarkable tale of success before. Cirrus Design was initially recognized in the realm of experimental aircraft during the 1990s for its VK30 pusher kit, an innovative composite design that gained traction in the kit market. However, by the mid-1990s, the visionaries behind Cirrus, Alan and Dale Klapmeier, embarked on a new journey, believing the time was ripe for a high-performance, composite fixed-gear single that could be safely flown by anyone.

The path they ventured on was far from effortless, but the resulting entry-level SR20 and flagship SR22, in their various iterations, have emerged as popular choices—both in the new and used aircraft markets. These aircraft exhibit impressive performance, and their dedicated and enthusiastic customer base is notably loyal. Owning a Cirrus makes you part of a tight-knit community of owners and pilots who consistently report high levels of satisfaction with the product. This loyalty paid off significantly when Cirrus took a bold step into the personal jet arena with the SF50 Vision Jet, seen as a logical progression from the SR22.

One of the standout features of Cirrus aircraft is the Cirrus Airframe Parachute System (CAPS), which has been responsible for numerous lives saved in emergency situations. At the time of this report in October 2022, there had been a successful activation of the CAPS system in the Vision Jet, preserving the lives of all three occupants after a challenging approach in adverse weather conditions. The proven effectiveness of CAPS has not only contributed to the success of Cirrus piston aircraft but is also expected to have a positive impact on the CAPS-equipped Vision Jet.

The lineage of the SR series commenced with the SR20, a model that continues to enjoy substantial demand in today’s market. However, it was the SR22, introduced in 2001, that emerged as the real crowd-pleaser. The initial SR22, often referred to as the G1, was cherished for its speed, though the SR20, primarily utilized for training purposes, certainly wasn’t sluggish either. The SR22 came equipped with a robust 310-HP Continental IO-500-N engine, widely regarded as one of Continental’s finest powerplants. Coupled with a three-blade propeller and enhanced payload capacity, the SR22 shared the same foundational airframe as the SR20, emphasizing operational simplicity.

To this day, Cirrus maintains its distinctive two-lever power control system, featuring a throttle and mixture lever but without a prop control lever. RPM settings are managed via a cable-and-cam mechanism, efficiently configuring the propeller for both takeoff and cruise. While the SR22’s airframe maintains a similar section to the SR20, several modifications set them apart. Notably, the SR22 features elongated wingtips, an enlarged rear elevator, and repositioned landing gear, ensuring greater ground clearance for the propeller.

Despite their shared sectional design, the SR22 incorporates a significantly reinforced main spar capable of accommodating more fuel, boasting 81 gallons in earlier models and 92 gallons in later versions. This transformation began with the G3, marked by a new wing and a carbon fiber spar. In contrast, the SR20 boasts a 60-gallon fuel capacity. The SR22 prioritizes passenger safety with energy-absorbing seats tailored to accommodate the aircraft’s higher weight.

Throughout the years, Cirrus has consistently prioritized crashworthiness. Later models introduce high-G seating and seatbelt airbags, enhancing passenger protection. Additionally, the cockpit configuration, featuring side-stick controllers, offers limited flail space, contributing to the aircraft’s robust structure and safeguarding occupants during CAPS deployments.

Cirrus subjected prototype fuselages to full-scale crash tests at NASA’s Langley facility in Virginia. These tests confirmed the impressive integrity of the composite fuselages, even under high impact loads. In the event of a CAPS activation, the descent under the canopy can reach speeds of up to 28 feet per second, translating to a vertical descent rate of 1,680 feet per minute or approximately 19 miles per hour. While a descent under the CAPS canopy is far from an ideal scenario, the majority of real-world deployments have resulted in no or only minor injuries.

The construction of Cirrus fuselages involves a process in which two halves are laid up in molds, joined together, and cured in an autoclave. The wings undergo a similar construction process, forming a single piece bonded to a substantial spar. This design creates a robust torsion box, proving its durability in real-world operational conditions. Unlike other aircraft manufacturers, such as Cessna and Diamond, Cirrus faces the challenge of de-winging, given its single-piece wing structure.

Cirrus, alongside Diamond, pioneered high-volume composite construction for light aircraft, achieving remarkable production efficiency. If you’ve had the opportunity to visit Cirrus’ production facility in Duluth, Minnesota, you’d have witnessed their proficiency in this regard.

Control surfaces on the SR22 are conventional, comprising riveted aluminum components. The control system employs a combination of push-pull tubes, cables, and bellcranks, complemented by a sidestick controller as opposed to a traditional yoke or center stick. Accessible via well-designed inspection panels, most of the control circuitry is situated beneath the floorboards.

The SR22 boasts a castering nosewheel with differential braking. While castering nosewheels can be maneuvered effectively with finesse, they do present some drawbacks, notably accelerated wear on brake pads. In the case of the SR22, this design initially led to a few brake-induced fires in early models, prompting an Airworthiness Directive (AD) mandating periodic O-ring replacement and the addition of a brake temperature inspection hole. Some owners have found that brake wear can be mitigated by avoiding excessive use of the brakes during taxiing. Cirrus eventually transitioned to Beringer wheels and brakes, resulting in the most impressive braking performance encountered in a piston single aircraft. However, the castering nosewheel, while facilitating effortless taxiing into parking spots, can pose challenges when manually pushing the aircraft into a hangar.

The SR22 G2 panel at the top has the original Avidyne Entegra PFD/MFD, plus retrofitted IFD navigators with a DFC90 autopilot. That’s the Garmin G1000 Perspective+ in the middle, and two round-gauge G1 models retrofitted with Garmin G5 flight displays (bottom left) and big-screen G500 TXi suites, right.

The SR22’s fuel system comprises wet cells situated in each wing. These cells are interconnected through a single tank switch, conveniently positioned on a console between the two pilot seats, within plain view and in proximity to the fuel level gauges. Owners of G1 and G2 models have reported issues with fuel gauge accuracy, prompting some G2 models to receive aftermarket digital fuel sender and control head upgrades by CIES. While the fuel within the wings is relatively well-protected, it may not offer the same level of protection as certain other aircraft, particularly those in the Diamond line. An examination of historical accidents reveals a slightly higher occurrence of post-crash fires in the SR22 when compared to Diamond aircraft.

Unlike many aircraft, SR22s do not rely on vacuum systems; instead, they are equipped with dual alternators and dual battery systems. This configuration offers a high degree of redundancy in the electrical system, featuring both a main and an essential bus. Both alternators are gear-driven, with one located at the front of the engine and the other attached to the rear accessory case. Considering the historical performance of Continental alternators, it is preferable to opt for a single belt-driven alternator. Nevertheless, the all-electric SR22 represents a significant leap forward compared to traditional vacuum instrument systems.

When it comes to avionics, a range of configurations is available. First-generation models come with round-gauge flight instruments, a single large-screen Multi-Function Display (MFD), and Garmin GNS 430 navigators within the radio stack. It is worth noting that a significant number of first-gen SR22s have undergone avionics upgrades, with Aspen retrofits being a popular choice. Furthermore, Garmin has obtained a limited number of Supplemental Type Certificates (STCs) for retrofitting glass displays. However, exercise caution when considering models equipped with Sandel’s SN3308 Electronic Horizontal Situation Indicator (EHSI).

In the early SR22 models, as well as in later-generation non-G1000 variants, you will typically encounter S-TEC autopilots. However, our preference leans toward those that have undergone retrofits with Avidyne’s digital DFC90 autopilots. Our experience has shown that S-TEC’s rate-based analog flight computer, which utilizes the turn coordinator as a roll reference, may not be ideally suited for the SR-22’s performance characteristics. Upgrading to the Avidyne DFC90 autopilot is a worthwhile enhancement, and it can be facilitated by retaining the existing S-TEC servos and replacing the computer/controller. Additionally, many owners opt for popular upgrades such as Garmin’s GFC 500, TXi, and GI 275 autopilot systems.

Cirrus cabins are comfortable and ergonomic dwellings. That’s a 2020 SR22T cabin at the top, a G2 with a Garmin TXi panel and upscale interior upgrade by NexAir Avionics, middle, and the 60/40 rear seating in a G5 model, bottom.

Second-generation SR22 aircraft were equipped with a complete Avidyne Entegra suite, featuring Garmin GNS navigators and a digital transponder. Avidyne has announced its ongoing efforts to develop a replacement for the Cirrus fleet, introducing the Vantage PFD/MFD suite.

The SR22-G3, introduced in 2008, incorporated Garmin’s G1000 Perspective avionics (although some G3 models retained Avidyne systems). This upgrade brought various enhancements, including synthetic vision, the integrated GFC 700 autopilot, and, in select aircraft, the EVS Enhanced Vision System equipped with an infrared camera. In 2017 and beyond, newer models were equipped with the G1000 Perspective+ version, featuring improved display clarity, faster processors, Surface Watch for runway guidance, visual approach capabilities, a Garmin Flight Stream wireless system, and the addition of Cirrus IQ. Cirrus IQ introduces an app that connects to the aircraft’s avionics via a cellular transceiver, along with flight and systems data logging and cloud storage capabilities. These advanced SR22-G6 models are highly sought after and typically sell rapidly for over $1 million.

TKS ice protection was available as an option in the late 2002 SR22s, but it wasn’t approved for known icing. That option didn’t appear until 2009.

Cirrus consistently introduced improvements to the SR22 lineup, catering to a customer base that eagerly embraced these upgrades.

Some were significant, while others contributed to the SR22’s sporty feel. Notably, a 6-point engine mount was introduced in the 2004 SR22-G2 model, along with a revamped cowl, a new prop, enhanced interior, and improved door latches.

In 2007, Cirrus unveiled one of its all-time bestsellers, the turbonormalized SR22. The demand for a turbocharged SR22 had long been voiced by customers. Although Cirrus had initially tried to develop an in-house turbo system, it couldn’t maintain the required cooling. Consequently, it turned to Tornado Alley Turbo to install a turbonormalized system under STC. These aircraft became exceptionally popular, even outselling the normally aspirated version at one point. Another modification option included the Forced Aeromotive FAT supercharger, providing a reported speed increase of 8 to 21 knots above 12,000 feet. The turbocharged SR22T, introduced in 2010, remains the preferred model today, featuring the Continental TSIO-550-K engine with a 2000-hour TBO.

In the late 2000s, Cirrus introduced more enhancements with the SR22-G3 models, which featured a redesigned wing boasting 92 gallons of fuel capacity, a carbon fiber spar, the elimination of the aileron-rudder interconnect from previous models, and improvements in environmental and interior ergonomics.

In 2013, the SR22-G5 emerged, marking a 500-pound gross weight increase, enhancing the useful load from 3400 pounds to 3600. The main spar was reinforced, landing gear strengthened, and additional composite layers added to the airframe. The 50 percent flap deployment speed increased to 150 knots from 119, making landing preparation easier. To maintain stall speeds at higher weights, flap deflection was increased to 35.5 degrees, necessitating strengthened flap components and a redesigned CAPS parachute.

Subsequent enhancements included LED wingtip lights and tubeless tires in 2014, as well as the introduction of the Mid-Continent SAM electronic standby instrument and cabin USB ports in 2015 models. ADS-B and angle-of-attack systems were added in 2016, along with a new key fob for remote door lock control.

The G6, introduced in 2017, brought Whelan-designed Spectra wingtip and ramp lighting, along with the altitude-sensing Halo automated wig-wag function. The Garmin Perspective+ avionics system became more sophisticated and, by 2020, included a takeoff and climb flaps warning system. Cirrus also elevated its paint and interior offerings, with the Carbon model featuring a sporty design, and the more luxurious Platinum and Rhodium schemes. Additionally, the Arrivee Special Edition version was introduced.

Some were significant, while others contributed to the SR22’s sporty feel. Notably, a 6-point engine mount was introduced in the 2004 SR22-G2 model, along with a revamped cowl, a new prop, enhanced interior, and improved door latches.

In 2007, Cirrus unveiled one of its all-time bestsellers, the turbonormalized SR22. The demand for a turbocharged SR22 had long been voiced by customers. Although Cirrus had initially tried to develop an in-house turbo system, it couldn’t maintain the required cooling. Consequently, it turned to Tornado Alley Turbo to install a turbonormalized system under STC. These aircraft became exceptionally popular, even outselling the normally aspirated version at one point. Another modification option included the Forced Aeromotive FAT supercharger, providing a reported speed increase of 8 to 21 knots above 12,000 feet. The turbocharged SR22T, introduced in 2010, remains the preferred model today, featuring the Continental TSIO-550-K engine with a 2000-hour TBO.

In the late 2000s, Cirrus introduced more enhancements with the SR22-G3 models, which featured a redesigned wing boasting 92 gallons of fuel capacity, a carbon fiber spar, the elimination of the aileron-rudder interconnect from previous models, and improvements in environmental and interior ergonomics.

In 2013, the SR22-G5 emerged, marking a 500-pound gross weight increase, enhancing the useful load from 3400 pounds to 3600. The main spar was reinforced, landing gear strengthened, and additional composite layers added to the airframe. The 50 percent flap deployment speed increased to 150 knots from 119, making landing preparation easier. To maintain stall speeds at higher weights, flap deflection was increased to 35.5 degrees, necessitating strengthened flap components and a redesigned CAPS parachute.

Subsequent enhancements included LED wingtip lights and tubeless tires in 2014, as well as the introduction of the Mid-Continent SAM electronic standby instrument and cabin USB ports in 2015 models. ADS-B and angle-of-attack systems were added in 2016, along with a new key fob for remote door lock control.

The G6, introduced in 2017, brought Whelan-designed Spectra wingtip and ramp lighting, along with the altitude-sensing Halo automated wig-wag function. The Garmin Perspective+ avionics system became more sophisticated and, by 2020, included a takeoff and climb flaps warning system. Cirrus also elevated its paint and interior offerings, with the Carbon model featuring a sporty design, and the more luxurious Platinum and Rhodium schemes. Additionally, the Arrivee Special Edition version was introduced.

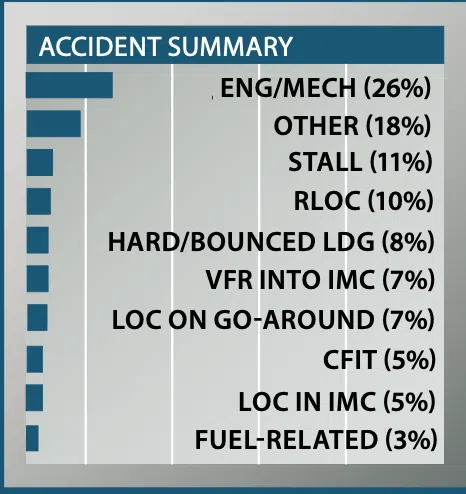

Upon analyzing the latest 100 Cirrus SR22 accidents, we noted an unusually low occurrence of fuel-related incidents. This positive trend could potentially be attributed to improved fuel gauges in more recent models. However, it was intriguing to find a relatively higher number of engine power loss incidents due to mechanical issues. What stood out even more was the fact that a vast majority of these power loss events resulted in no or minor injuries.

Out of the 26 engine power loss incidents, the CAPS system was deployed in 21 cases by either the pilot or a passenger. In all of these instances, every occupant survived the descent under the canopy, even in situations where strong winds caused the aircraft to be displaced or overturned after landing.

In these incidents, there were occasional minor injuries involved—a notably more favorable outcome compared to engine-out events in aircraft lacking a ballistic parachute system. Typically, such aircraft experience at least six fatalities out of every 20 engine-out accidents.

Out of the five engine power loss accidents where the CAPS remained unused, injuries and fatalities did occur. It’s worth noting that in two of these accidents, the aircraft was positioned at an altitude too low to deploy the CAPS.

Upon closer examination, we observed that the root cause of engine power loss in nearly every case was improper maintenance. Issues such as improperly torqued cylinders, loosely secured fuel fittings, non-compliance with airworthiness directives (ADs), and excessively rich fuel flow settings at full power were consistently identified as contributing factors.

In our analysis, we identified five loss of control (LOC) accidents that occurred in instrument meteorological conditions (IMC). One of these accidents stemmed from a pilot’s overreliance on the autopilot and an inability to program it correctly. Fortunately, three out of the five LOC incidents had positive outcomes, as the pilots effectively utilized the CAPS system, resulting in the survival of all occupants. The other two IMC LOC accidents were linked to airframe icing. It remains unclear why the pilots chose not to engage the CAPS, which represented their last resort in such situations.

We expressed our concerns regarding the frequency of landing accidents. While there was only one runway overshoot, nine pilots experienced a loss of control after landing, seven lost control during a go-around, and eight experienced damage to their SR22 aircraft after a hard or bounced landing, often leading to pilot-induced oscillations (PIO). In our assessment, it is imperative for Cirrus pilots to undergo recurrent training in crosswind landings.

Furthermore, we recorded seven crashes involving Cirrus pilots who opted to venture into instrument meteorological conditions (IMC) under visual flight rules (VFR). In most cases, these pilots willingly ventured into IMC conditions despite their awareness of the risks. The NTSB documented an anti-authority attitude in one of the pilots involved in these accidents, and we observed that this attitude likely played a role in at least half of the other incidents. It was notable that none of the pilots who made this risky choice opted to use the CAPS when the situation deteriorated, despite having sufficient altitude to do so.

One SR22 pilot chose not to activate the runway lights during a night landing, resulting in contact with the windsock before touchdown.

In another incident, after a pilot and a rear-seat passenger unbelted to retrieve an item under the pilot’s seat, the right-seat passenger attempted to assist by adjusting his seat. In doing so, he inadvertently manipulated his sidestick rapidly three times, causing both the pilot and the rear-seat passenger to repeatedly strike the ceiling, resulting in severe injuries to the rear-seat passenger.

The SR22 is subject to a total of 14 airworthiness directives, indicating a moderate overall compliance burden. While none of these directives are particularly daunting or costly, a few of them do hold significance for safety considerations. Notable examples include AD 2008-14-13, which mandates door hinge replacement to prevent the door from separating from the aircraft, AD 2008-06-28, addressing important Avidyne PFD issues, and AD 2007-14-03, which necessitates modifications to the CAPS activation system.

Speaking of the CAPS (Cirrus Airframe Parachute System), the earliest aircraft have reached the point where a 10-year repack and recertification are due.

Kirk Goodell’s 2003 turbonormalized SR22 Centennial Edition. One of 100 produced, it’s a tribute to the Wright Brothers’ 100 years of flight.

This service typically costs around $14,000 when utilizing an overhauled unit, but comes close to $16,000 for a new one. In the case of G1 aircraft, this process involves expensive composite repair and paint work. However, starting with G2 models and beyond, the CAPS can be accessed through the baggage area, eliminating the need for structural alteration.

In 2013, I made the transition to an SR22-G2, upgrading from a Piper Warrior. My primary goal was to acquire an affordable IFR (Instrument Flight Rules) aircraft for regular visits to my company, which was a four-hour drive from Munich, Germany to the Czech Republic. At my destination, there was a 2000-foot grass strip, well-suited for the SR22, even in challenging conditions like hot weather and near its maximum takeoff weight.

Adapting from the Warrior with its low wing loading was a gradual process, and it took some time to become accustomed to the higher speeds and the sophisticated glass cockpit of the SR22. Fortunately, Cirrus offers a fantastic complimentary training program called Embark for all Cirrus buyers, regardless of the age of their aircraft. This program provides up to 10 hours of instruction led by a Cirrus Standardized Instructor Pilot (CSIP).

Common to all SR22s, pictured top to bottom: a castering nosewheel, a CAPS parachute and a Continental 550-series engine.

While this airplane is relatively straightforward to operate, it requires strict adherence to proper procedures, especially during approach and landing, focusing on maintaining precise speeds and following established guidelines. With the right training, I can confidently operate my SR22 from grass strips as short as 1600 feet, proving that it can handle challenging conditions when piloted correctly.

I made several upgrades to my G2, including the installation of Avidyne’s DFC90 autopilot, Garmin WAAS navigators, and a four-blade propeller, resulting in an exceptional flying experience. To keep maintenance costs down and considering that most of my typical routes involve relatively lower-altitude flying over smaller mountains, I opted for the normally aspirated model. This configuration allows me to achieve speeds of 165-170 knots at 10,000 feet with a fuel consumption of approximately 14 gallons per hour while operating in a lean-of-peak condition.

On occasion, I cross the Alps en route to the Mediterranean, and this is typically manageable when cruising between 12,000 and 16,000 feet. However, if such trips became more frequent, I might consider a turbonormalized version of the aircraft to enhance high-altitude performance.

I find great joy in flying this aircraft, particularly appreciating its precision approach capabilities thanks to the advanced avionics. The availability of optional air conditioning and a spacious cabin adds to its appeal, making it ideal for occasional family trips.

In terms of safety, I’ve grown increasingly fond of having the BRS (CAPS) system on board—it provides a reassuring layer of security.

Throughout my nine years of ownership, this aircraft has proven to be reliable, with only two days of downtime. Our maintenance team identified a slightly burned exhaust valve and low compression during a borescope inspection at 1400 hours, leading us to replace a cylinder.

However, I do wish that the aircraft had manual elevator trim and rudder trim, which would enhance comfort during long climbs to higher altitudes. It’s worth noting that newer G1000 Perspective-equipped models come with a yaw damper, addressing this concern.

Alex von Croy – Munich, Germany

I’ve been the owner of a 2006 Cirrus SR22TN since 2018. My decision to go for the Cirrus came after considering glass panel upgrades for my A36 Bonanza. At that time, I could acquire an all-electric glass-panel Cirrus for around $200,000, while a similarly equipped A36 would cost approximately $500,000. My primary objectives were to have automation, integrated avionics, and improved situational awareness, and I certainly got all of that and more.

Initially, I was hesitant about the parachute system, seeing it as an unnecessary $15,000 expense every decade. However, as time went on, coupled with hours of training, I began to view it as an ejection seat for my family. It brings comfort to my in-laws, and my wife, who is also capable of flying the plane, appreciates having it as an added safety feature. I’ve come to realize that my initial reservations about the parachute were somewhat biased, as safety should always come first. I’m now glad that the plane is equipped with it, especially as we move towards a future with technologies like Garmin Autoland and autonomous autopilots, where safety remains paramount.

The transition from a round-gauge panel to a glass cockpit cannot be understated. To be honest, it took me some time to adapt. During the first 20 hours, I felt like I was lagging behind the aircraft, but over the next 30 hours, I gradually grew comfortable. It took a total of 150 hours before I reached a point where I knew exactly where to look and when to interact with the avionics effectively, allowing me to stay ahead of the aircraft. It’s worth noting that I had no prior experience with approach-coupled GPS and had only used the Direct-To GPS function. However, once I had everything figured out, my initial expectations of having a higher level of situational awareness were realized, and it’s truly remarkable. I still have reservations about not having control over the propeller, but the single-lever power control system works well.

The Cirrus is a well-thought-out aircraft in many aspects, but it seems to have some areas of compromise that could have been avoided. One notable example is the landing gear. The main gear, which is similar to that of a Cessna, is robust and predictable. However, the nose gear, like in many other aircraft, presents its challenges. It uses a rubber puck system that Mooney pilots would find familiar and requires constant monitoring and careful handling. Earlier models, up to the G2, had a shorter nose gear stance, which was extended in G3 and newer models. Regardless of the changes, the same nose gear system, albeit improved, remains in place. Rough, flat landings have resulted in prop strikes, leading Cirrus owners to undertake engine teardowns. The full castering nosewheel is convenient on the ramp for easy maneuvering within your wingspan, but it’s essential to straighten it out before applying a load, such as during a run-up.

As you can see here, Cirrus really stepped up its customized paint work. That’s Justin Winter’s good-looking 2019 SR22 at the top.

The wings on this aircraft give off a strong impression of sturdiness, yet their stall characteristics are incredibly forgiving. However, I often find myself wishing for more fuel capacity, considering it can hold 86 gallons. A trip from Michigan to Florida practically requires learning Georgian just to fill the tanks. While theoretically, I could reach well into Florida without refueling, my past experiences have made me prefer a stress-free journey over the radio towers, dealing with busy approach controllers and the typical general aviation traffic while carrying just half tanks, making it easy to manage during landing.

This aircraft’s wings are equipped with TKS de-icing, and it functions exceptionally well. However, it’s essential to note that this aircraft isn’t FIKI (Flight into Known Icing) certified, as it relies on a single TKS pump.

Personally, I would appreciate a larger TKS tank, but that’s just a personal preference. Up to this point, I’ve never required a full tank, but if you encounter unexpected icing conditions, you’ll be closely monitoring the clock. The flap system in my G2 is highly effective, offering 50 percent deployment below 120 knots and full 100 percent extension at 104 knots.

The airplane is responsive in roll and feels adequately coordinated. The side stick control forces are appropriately firm for a cross-country aircraft, although you won’t be executing aggressive maneuvers for the sheer thrill of it, even though the plane handles exceptionally well. Lastly, it’s worth mentioning that each wing has two fuel sumps, so hands-and-knees preflight inspections are standard for low-wing aircraft and best done within the shelter of the hangar during harsh Michigan winters.

This turbocharged aircraft comes equipped with onboard oxygen, and this year, it required a new $4,000 tank from Precise Flight because it reached its service life limit. To ensure redundancy and safety lessons learned from high-altitude flights with adverse weather conditions below, I always carry portable oxygen bottles as backup.

The modification landscape for this aircraft is a bit different from other planes since Cirrus has tightly controlled the development. Most of the valuable modifications have been integrated into the factory, making them exclusively available through Cirrus at a premium. In my experience, Cirrus is exceptionally responsive as a company and organized in their training programs. Your opinion of their training structure will depend on your preference for self-determination. My primary concern is the lack of support for Avidyne-equipped planes after Cirrus transitioned to Garmin. As far as training goes, it’s virtually non-existent for Avidyne models. Finding a Cirrus Standardized Instructor Pilot (CSIP) with Avidyne experience is essential if you purchase an Avidyne-equipped aircraft. Cirrus has a strong focus on the Garmin suite, and Avidyne model owners are essentially left to fend for themselves.

Finding insurance has been relatively straightforward for me. I’m 65 years old, hold a multi-engine and instrument rating, and have logged over 3,000 hours of flight time. The insurance requirement for me is to fly with an instructor once a year, costing around $3,400 annually for a $270,000 hull value. While not inexpensive, it’s within a reasonable range based on my experience, though costs are on the rise. The S-TEC 55X autopilot represents a significant improvement over a King 150 autopilot. However, it may not perform as well in crosswind conditions or during ILS approaches.

Annual inspections are manageable as long as no items fall out of their calendar due dates or involve airworthiness directives (AD) or service bulletins. Addressing these additional issues can add to the base inspection rate, which typically starts at $3,000. During my recent inspection, both exhaust manifolds needed replacement with newer versions, amounting to $6,500 and triggering my carbon monoxide detector.

To prolong brake life, it’s advisable to avoid excessive braking when taxiing, especially with full rudder deflection. A series of airworthiness directives, including one for seatbelt airbags and another for converting the parachute activation to electric, required kits from the factory. The aircraft’s various systems and complexity do require ongoing maintenance, and this year, I had to replace my leaky magnetos with a rebuilt unit and a SureFly electronic unit. It has improved hot starts, which can be quite challenging. After enduring a four-hour grounding at an airport that lacked a 28-volt charger or jump-starter, I became determined to master hot starts. From numerous attempts, I’ve found that, when hot, turning the key with the throttle at 1/4-inch, mixture cutoff, no fuel pump, and slamming the mixture to full rich as the engine catches (along with clenching your cheeks and holding your breath) seems to work best. There’s little room for error with hot starts, and grinding the starter may lead to a starter replacement. To avoid such situations, I now carry a 28-volt APU LiPo pack with an APU plug to spin the prop like a fan.

Embarking on a cross-country journey in this aircraft is akin to sitting in a BMW. It features comfortable seats, large displays with XM weather, ADS-B weather, Stormscope, and satellite music. The airplane handles turbulence smoothly, and the turbocharged engine allows us to navigate through challenging weather conditions and over mountains with confidence. It’s an extremely capable machine, and my dispatch reliability has remained at 100 percent. Additionally, I installed the L3 Lynx ADS-B transponder, which I can’t praise enough for its performance and functionality.

Will I consider buying another Cirrus? If I do, it would be to acquire the Garmin avionics suite, an additional 12 gallons of fuel capacity, and the improved landing gear featured on the G3 and later models. If Cirrus were to offer a six-seater with a turbo diesel engine, similar to my former A36, I’d make the purchase without hesitation, even if it were a factory-new model. For now, I have an incredibly automated and capable IFR cross-country machine that meets my needs within this segment of general aviation spending. To attain more, I’d need to double my investment without significantly increasing my speed or safety for my family. So, I’m content, flying a modern, reliable aircraft that I have complete confidence in.

Kirk Goodell – via email

Kirk Goodell says that every flight in his SR22 feels like a checkride

I own a 2019 SR22 and previously sold my 2006 SR22 GTS to acquire this one. I chose a clean-wing model without TKS, as I reside in South Carolina where icing encounters are quite limited. I also opted not to have air conditioning, considering I mainly fly early in the morning during the cooler seasons to avoid convective weather buildups. This decision also minimizes the potential for engine accessories to malfunction.

My aircraft boasts a remarkable useful load of 1326 pounds, allowing me to accommodate 774 pounds of passengers and cargo comfortably. This translates to three adult passengers, 100 pounds of cargo in the storage bin, and a full 92-gallon fuel load. I have yet to come across another SR22 with a higher useful load.

The delivery experience from Cirrus in Knoxville was truly memorable. It included three days of training with my new plane, and I was delighted to have my family join me during this time. It provided them with a glimpse into the people behind Cirrus. The online Cirrus Approach learning portal proved invaluable, offering comprehensive instruction in the Flight Operations Manual and various professional-quality “flying fixes” through videos.

I have logged 496 flight hours in my 2019 SR22 and typically fly around 150 hours each year. I couldn’t be more pleased with my aircraft and its performance.

My annual expenses, which encompass insurance ($5,600), hangar fees ($4,200), maintenance ($1,600), annual inspection ($3,800), and fuel, amount to approximately $25,000, or just under $170 per flight hour. This estimate excludes the initial capital cost.

I genuinely believe that there isn’t another single-engine aircraft on the market that matches the SR22 in terms of speed, reliability, and low operating costs. It stands out as an exceptional choice, offering a unique combination of price, economy, speed (182 knots ROP), passenger capacity (seats five), safety with CAPS, and impressive range (1,000 NM and 5.5 hours with reserves).

Justin Winter – via email

At Flying Finance, we’re your trusted partner in aviation financing. With a deep understanding of the aviation industry and a commitment to making your dreams take flight, we provide tailored financing solutions for business jets, piston aircraft, turboprop aircraft, helicopters and more. A financier who understands aviation.

© 2024 Flying Finance. All rights reserved. Privacy Policy